-

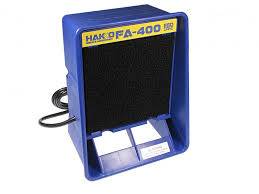

Smoke Absorber (P/N: T00308)

– Removes soidering fumes quickly, safely and efficiently

– Power: 13W/15W

– Domensions 166(W) x 212(H) x 113(D)mm

– Weight: 0.93 kg -

Thermometer (P/N: T00023)

– Test the temperature of soodering iron precisely and quichky

– Clear LCD indication

– Sensors are esay to be replaced

– Wide testing temperature range of 0 C – 600 C -

Thermometer (P/N: T00315)

– Providing reliable temperature control of soidering tips

– Compact design saves your workspace and allows

you to carry it around easily

– Extremely fine sensor with high temperature reactivity

is incorprated -

ESD Soldering Station (P/N: T00221 )

– High frequecy curent heating element

– Fast heating and temperature recovery

– Auto – Idle prolongs the top life, energy-saving

– Password option for temperature lockingTemperature Range: 500 – 600 C

Output Viltage / Frequency: 36V AC / 400 KHz

Max Power: 90W

Applicalbe Tipe: 200 series

Dimenesions: 130(W) x 100(H) + 200(D)mm

Weight: 2.6 Kg -

ESD Soldering Station (P/N: T00220)

– Supperior heat recovery. Digital display

– Temperature locking system; sleep mode

– Temperature compensation; low temperature alarm

– Somposite tip of excellent thermal recovery and

accurate temperature setting.Power Consumpotin: 75W

Temperature Range: 200 – 450 C

Output Viltage: 24V

Applicalbe Tipe: T12 series

Dimenesions: 800(W) x 130(H) + 131(D)mm

Weight (w/o cord): 1.2 Kg -

ESD Soldering Station (P/N: T0021 8)

– Digital display ensure accurate temperature setting.

– Once set, tempertature cannot be changed without

inserting the key card

– Adopting Japan long life ceramic heater

– Handle is especially light, easy to operater.Power Consumpotin: 60W

Output Viltage: 24V AC

Heating Element: Ceramoc Heater

Temperaturre Range: 200 C ~ 480 C

Applicable Tips: 900 Series -

ESD Soldering Station (P/N: T00028)

– Adopting Japan long life ceramic heater

– Handle is especially light, easy to operater.

-Temperature reises quickly. Stableand accurate

templerature control.Power Consumpotin: 60W

Output Viltage: 24V AC

Heating Element: Ceramoc Heater

Temperaturre Range: 200 C ~ 480 C

Applicable Tips: 900 Series -

BGA Rework Station (P/N: T00329)

– 3 independent Heating System

You can use software to choose to use top heater or bottom heater separatey or conbine the top and bottom heater’s capacity, so as to make it easier

to rework double BGA, CCGA, QFN, CSP, LGA, SMD, etc.

– Precise Optical Alignment System

Clear inmages with a 12st HD monitor, compoments can be enlarged up to

maximum 230 times, mounting accuracy within +- 0.001mm, with a beam

split, zoom in, zoom out and fine – tunning fincutions.

– Multi-funciton Openration System

With touch screen interface, k-type thermocouple and intelligent temperature compesation, intergrated design of top heater and sucker

point; it can auto identify a high degree of suction and mouting; with automatic soidering and desoidering functions; temperature can be

set to 6 segmets and 6 segment constant tempertature conrtol can save N groups of temperature setting parameters for different kinds of

BAG ship sets.

– Superior Safety Functions

Affter finish desoidering and soidering, there is alrming; when temperature goes out of control the circit will automatic power off, it is of

double excess temperature protection function. Apassword is needed for tempertature parameter to avoid random changesTotal Power: 4800W Max

Top Heater Power: 800W (1st heater)

Bottom Heater Power: 1200W (2nd heater)

3rd IR Heater: 2700W

Dimensions: 640 x 630 x 900mm

Temperature Control: K-type thermocouple (closed loop control)

Positioning: V-groove, with external iniversal fixture

PCB Size: Max: 410 x 370mm Min: 65 x 6mm

Available BGA Chip: 1 x 1mm – 80 x 80mm

External Temperature Sensor: 1piece

Net Weight: 40Kg -

BGA Rework Station (P/N: T00328)

– With the liner slide, all the X, Y, X axis can do precision adjustment and fast

positioning

– HD touch screen, PLC control, can save multiple sets of temperature

profile data; with instant temperature curve analysis function

– 3 independent heating areas from top on to bottom. The 1st and 2nd are

hot air heaters, the 3rd is IR preheating, temperature controlled within +- 3

C –

Offer all kinds of hot air nozzles which can rotate 360; with magnet, easy to install and change

– Use a V-groove equipped with a flexible fixture for PCB positioning to protect the PCB from deformation when heated or cooled; it can

rework any BGA package size

– Powerful cross-flow fan rapidty cool the PCB to improve efficiency; Also built-in vacuum pump and external vacuum suction pen, pick

up the Chips rapidtyTotal Power: 4800W

Top Heater Power: 800W

Bottom Heater Power: 2nd heater: 1200W, 3rd IR heater: 2700W

Dimensions: 635 x 600 x 560mm

Positioning: V-groove, with external iniversal fixture

Temperature Control: K-type thermocouple (closed loop control)

PCB Size: Max: 410 x 370mm Min: 20 x 20mm

Net Weight: 40KgXem tiếpThe product is already in the wishlist!Browse Wishlist

- Home

- >

- Soldering & Reworking Tools (Trang 6)